How to Insulate an Attic for Maximum Energy Efficiency

How to Insulate an Attic for Maximum Energy Efficiency

Need to insulate an attic? This guide will show you how to assess your current attic insulation, choose the right materials, and install them correctly for better energy efficiency and comfort.

Key Takeaways

- Assess current attic insulation for thickness and integrity, ensuring it meets recommended R-value and is free from moisture or mold.

- Choose the right insulation material, considering options like loose fill, batt, or spray foam, and prepare the attic by sealing air leaks and ensuring proper ventilation.

- Upgrading attic insulation can lead to significant energy savings, improved home comfort, and increased Home value, balancing options between DIY and professional installation for optimal results.

Assess Your Current Attic Insulation

Begin by evaluating your current insulation. This helps identify areas needing improvement and ensures your efforts are effective. The first thing to check is the thickness of your existing insulation. Experts recommend an insulation thickness of R-30, which translates to about 10 to 13 inches.

Check for visible signs of moisture or mold, which indicate degraded insulation needing replacement. These issues not only reduce insulation effectiveness but also pose health risks and can damage your home’s structure.

Finally, ensure that insulation is applied between and over the floor joists in unfinished attic spaces. Properly insulating both the floor and the rafters is essential for optimal air distribution, which helps maintain a consistent temperature throughout your home.

Choose the Right Insulation Material

Choosing the right insulation material can seem overwhelming, but it doesn’t have to be. The most common types used in attics are loose fill insulation and batt insulation. Loose fill insulation, like cellulose or fiberglass, is excellent for filling gaps and providing comprehensive coverage. It’s particularly useful in attics with irregular or hard-to-reach spaces.

Batt insulation, on the other hand, comes in pre-cut panels that fit snugly between ceiling and floor joists. Fiberglass batts are a popular choice due to their ease of handling and installation, making them a favorite for DIY projects. However, batt insulation requires careful cutting and fitting to avoid gaps that can compromise its efficiency.

For superior moisture control, consider spray foam or blown-in cellulose. Closed cell spray foam, either closed-cell or open-cell, offers an airtight seal that greatly reduces air leaks and moisture infiltration. Your choice of material will also depend on factors like your attic’s size, the local climate, and any existing insulation materials.

Check local building codes for required R-values to ensure your rigid foam insulation meets minimum standards for energy efficiency and safety. By choosing the right insulation material, you’ll set the foundation for a more comfortable and cost-effective home.

Prepare the Attic for Insulation Installation

Proper preparation is key to the success of any insulation project. Before you begin installing insulation, it’s essential to clear and clean the attic space, seal any air leaks, and ensure proper ventilation. These steps not only make the installation process smoother but also enhance the overall effectiveness of your insulation.

Starting with a clean slate ensures that no debris or stored items interfere with the insulation process. Additionally, sealing air leaks prevents unwanted airflow and maintains the integrity of your insulation. Lastly, proper ventilation is crucial to avoid moisture buildup, which can damage your insulation and reduce its efficiency.

Clear and Clean the Attic Space

Remove all boxes, storage items, and debris from the attic. Though tedious, this step is vital for optimal insulation performance. Items stored directly on top of insulation can compress it, reducing its effectiveness by up to half. To expedite this process and keep the area clean, consider renting a dumpster for disposal of unwanted items.

Once the attic is clear, thoroughly clean the space. A clean workspace not only makes the installation process easier but also ensures that the insulation adheres properly and functions as intended. With a clutter-free attic, you’re ready to move on to sealing air leaks.

Seal Air Leaks

Air leaks can significantly undermine the effectiveness of your attic insulation. Common areas for leaks include around recessed lighting, attic access points, and any other openings. To identify these leaks, use a pen and notepad to mark problem areas as you inspect the attic.

Once you’ve identified the leaks, use materials like foam sealant, weatherstripping, and caulking to seal them. This process is crucial for achieving proper air sealing, which prevents unwanted airflow and enhances the efficiency of your insulation. Remember, the first step to effective insulation is ensuring that no air can bypass it.

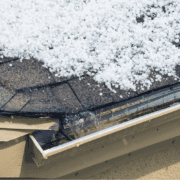

Sealing air leaks also prevents issues like ice dams in cold climates, formed by warm air escaping into the attic and melting roof snow. This ensures your insulation works effectively without air seal interference.

Ensure Proper Ventilation

Ventilation is a key component of a healthy attic. Without proper ventilation, moisture can build up, leading to mold growth and insulation damage. Keep external soffit vents clear to maintain good airflow into the attic.

In cathedral ceilings, it’s essential to have a space between the roof deck and the home’s ceiling for proper insulation and ventilation. Installing vent baffles in these spaces helps maintain a clear ventilation channel, ensuring that air can flow freely and prevent moisture buildup, especially when considering the role of roof decking.

Using roof and ridge vents to allow hot air to escape is also essential. This protects your insulation and helps regulate your home’s temperature, ensuring year-round comfort.

Install the First Layer of Insulation

Once the attic is prepared, install insulation as the first layer to create an initial barrier against heat loss and air leaks. Depending on your choice of insulation, the installation process may vary.

We’ll cover the details for loose fill insulation and batt insulation in the following subsections. Using a blower machine can help speed up the process for loose fill insulation, while batt insulation requires careful cutting and fitting to avoid gaps and over-compression.

Follow best practices to avoid common issues such as trapped moisture or under-insulated areas.

Loose Fill Insulation

Loose fill insulation, such as cellulose or fiberglass, is an excellent choice for attics with irregular spaces or hard-to-reach areas. To calculate the amount needed, divide your attic’s square footage by 1,000 and multiply by the desired R-value. This will give you a good estimate of how much insulation to purchase.

When installing loose fill insulation, it’s important to remove any existing vapor barriers. Vapor barriers can trap moisture, which can degrade the insulation over time. Using a blower machine, blow in the loose fill insulation evenly across the attic floor, ensuring there are no gaps or compressed areas. This method minimizes airborne particles and ensures thorough coverage.

If necessary, add a second layer using fiberglass batts to fill any remaining gaps for optimal results. This combination of loose fill and batt insulation creates a comprehensive barrier that significantly improves your attic’s energy efficiency.

Batt Insulation

Batt insulation, typically made of fiberglass, is designed to fit snugly between ceiling and floor joists. When installing batt insulation, make sure to cut it to the appropriate size, allowing for a tight fit without gaps. This ensures that the insulation performs effectively, providing a consistent thermal barrier.

Avoid over-compressing the batts, as this can restrict airflow and reduce their insulating capacity. Properly installed batt insulation should be placed snugly against the joists to prevent air leaks and maximize energy efficiency. For added effectiveness, consider placing a second layer of insulation perpendicular to the first, covering any remaining gaps.

Following these steps creates a solid foundation of insulation, significantly improving your home’s energy efficiency and comfort.

Add a Radiant Barrier

Radiant barriers are an excellent addition to your attic insulation strategy, especially in warm climates. These barriers reflect heat away from living spaces, reducing ceiling heat gains by up to 42% in some cases. They are particularly effective in attics with insulation levels like R-19.

For optimal performance, install a perforated radiant barrier on the rafters or on top of the first layer of insulation. Overlap sections by 1–2 inches to maintain a continuous barrier. If the insulation does not protrude above the floor joists, use a staple gun to secure the radiant barrier in place.

Be mindful of dust accumulation on the radiant barrier, as this can diminish its effectiveness over time. Regular maintenance and cleaning can help maintain its reflective properties, ensuring long-term energy savings and improved comfort.

Insulate the Attic Opening

The attic opening is often overlooked but can be a significant source of energy loss. Insulate all entrances, including doors, hatches, and stairs. For simple doors or small entrances, affix insulation to the attic side of the door. This prevents warm air from escaping and cold air from entering.

For attic stairs, consider using an attic stair insulator. This can be a more cost-effective option but requires careful installation to ensure a proper seal. Alternatively, you can purchase an insulated zippered tent cover, which is easier to install but might be more expensive.

Failing to properly seal the attic entrance can result in missed energy cost savings.

Safety Precautions During Insulation

Safety should always be a priority when installing insulation. When handling fiberglass insulation, wear gloves, long sleeves, safety glasses, and a dust mask to protect against skin and respiratory irritation. For cellulose insulation, respiratory protection is essential due to its irritant properties.

Spray foam insulation contains chemicals that can trigger respiratory issues if safety measures are not followed. Ensure proper ventilation and use protective gear when applying spray foam. If you’re unsure about handling these materials, consider hiring professional contractors who are trained in safety protocols.

Proper insulation installation improves energy efficiency and ensures your health and safety. Follow these precautions to avoid common risks and achieve optimal results.

Benefits of Upgrading Attic Insulation

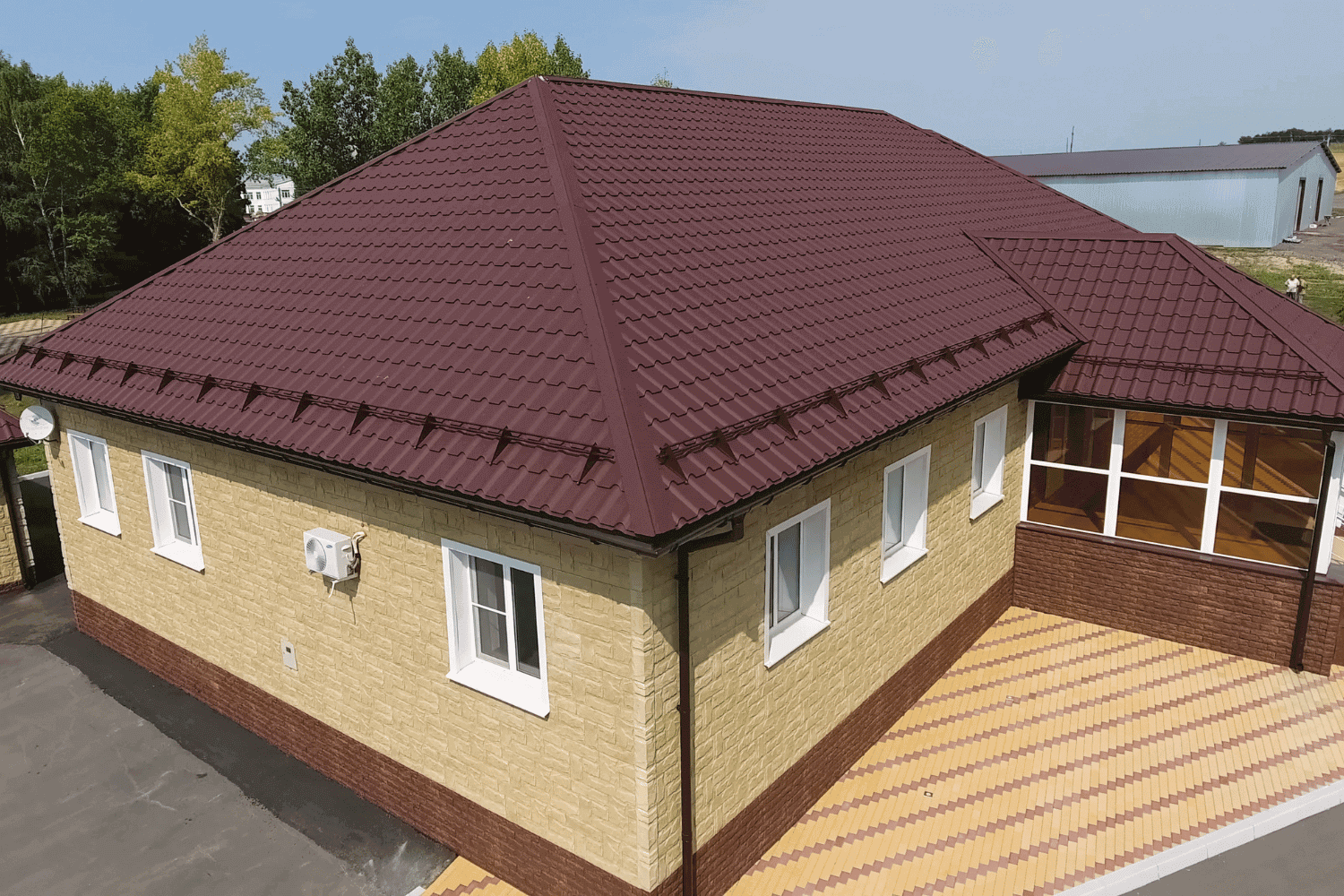

Upgrading your attic insulation offers numerous benefits, starting with significant energy savings. Proper insulation can reduce your energy bills by up to 20%, making it a smart investment for long-term savings. Inconsistent room temperatures and drafts often indicate inadequate insulation, which can be resolved by upgrading your attic insulation.

Beyond economic benefits, proper insulation enhances comfort by maintaining consistent temperatures, reducing HVAC strain, and improving indoor air quality. Upgraded insulation also adds home value, making it a worthwhile investment for potential sales.

By upgrading your attic insulation, you create a more energy-efficient and comfortable living environment, contributing to both immediate and long-term benefits.

Professional vs. DIY Insulation

When deciding between professional and DIY insulation, there are several factors to consider. DIY insulation can provide significant cost savings by eliminating labor expenses, with potential savings ranging from $440 to $680. Affordable options for DIY projects include blanket (batt and roll) insulation, which can often be completed in a weekend.

However, DIY insulation poses risks of errors that could lead to energy loss and higher costs over time. Incorrect installation can result in gaps, over-compression, or inadequate coverage, all of which reduce the insulation’s effectiveness. These mistakes can negate the initial cost savings and lead to increased energy bills in the long run.

On the other hand, hiring professionals ensures proper installation, which is crucial for the effectiveness of your attic insulation. Professional contractors are trained in safety protocols and have the expertise to handle different insulation materials and techniques. They can also identify potential issues that a DIYer might overlook, ensuring that your insulation provides maximum energy efficiency and comfort.

Summary

In summary, insulating your attic involves several critical steps: assessing your current insulation, choosing the right materials, preparing the attic, installing the insulation, and ensuring proper safety measures. Each step contributes to creating an effective barrier that enhances your home’s energy efficiency and comfort. Whether you opt for loose fill insulation, batt insulation, or a combination of both, following best practices ensures optimal results.

Upgrading your attic insulation is a worthwhile investment that offers long-term benefits, including reduced energy bills, consistent indoor temperatures, and increased home value. By taking the time to properly insulate your attic, you can create a more comfortable and energy-efficient living environment. Ready to transform your attic into an energy-saving asset? The journey starts now.

Frequently Asked Questions

What problems do many Indiana homeowners face regarding their homes?

Many Indiana homeowners face issues with uncomfortable rooms and elevated utility expenses. Addressing these problems can lead to a more comfortable and cost-effective living environment.

How can upgrading attic insulation benefit homeowners?

Upgrading attic insulation is essential for homeowners as it significantly enhances comfort by preventing heat loss or gain, ultimately reducing HVAC usage and energy costs. Improved insulation leads to a more efficient home environment.

What is a common issue for homes older than five years regarding attic insulation?

A common issue for homes older than five years is insufficient or missing attic insulation, which can lead to higher energy costs and reduced comfort. It’s essential to evaluate and upgrade your insulation to maintain efficiency.

How can attic insulation affect energy bills?

Attic insulation significantly reduces energy bills by creating a barrier that retains heat in winter and cool air in summer, which can lead to savings of up to 20%. Investing in proper insulation is a cost-effective way to enhance energy efficiency in your home.

574-318-3326

574-318-3326