Fascia Board Basics: Everything Homeowners Need to Know

Fascia boards are horizontal boards along the roof edge. They support gutters and protect your home from weather damage. This guide explains the role of fascia boards, their importance, material options, and maintenance tips related to fascia boards. Understanding the function of the fascia board is essential for any homeowner.

Key Takeaways

- Fascia boards are crucial for supporting roof structures and protecting attics from weather damage while enhancing a home’s aesthetics.

- Choosing the right fascia material—wood, PVC, composite, or aluminum—depends on climate, budget, and desired style, impacting durability and maintenance needs.

- Regular maintenance, including inspections and cleaning, is essential for prolonging the life of fascia boards and ensuring they effectively protect your home.

Understanding Fascia Boards

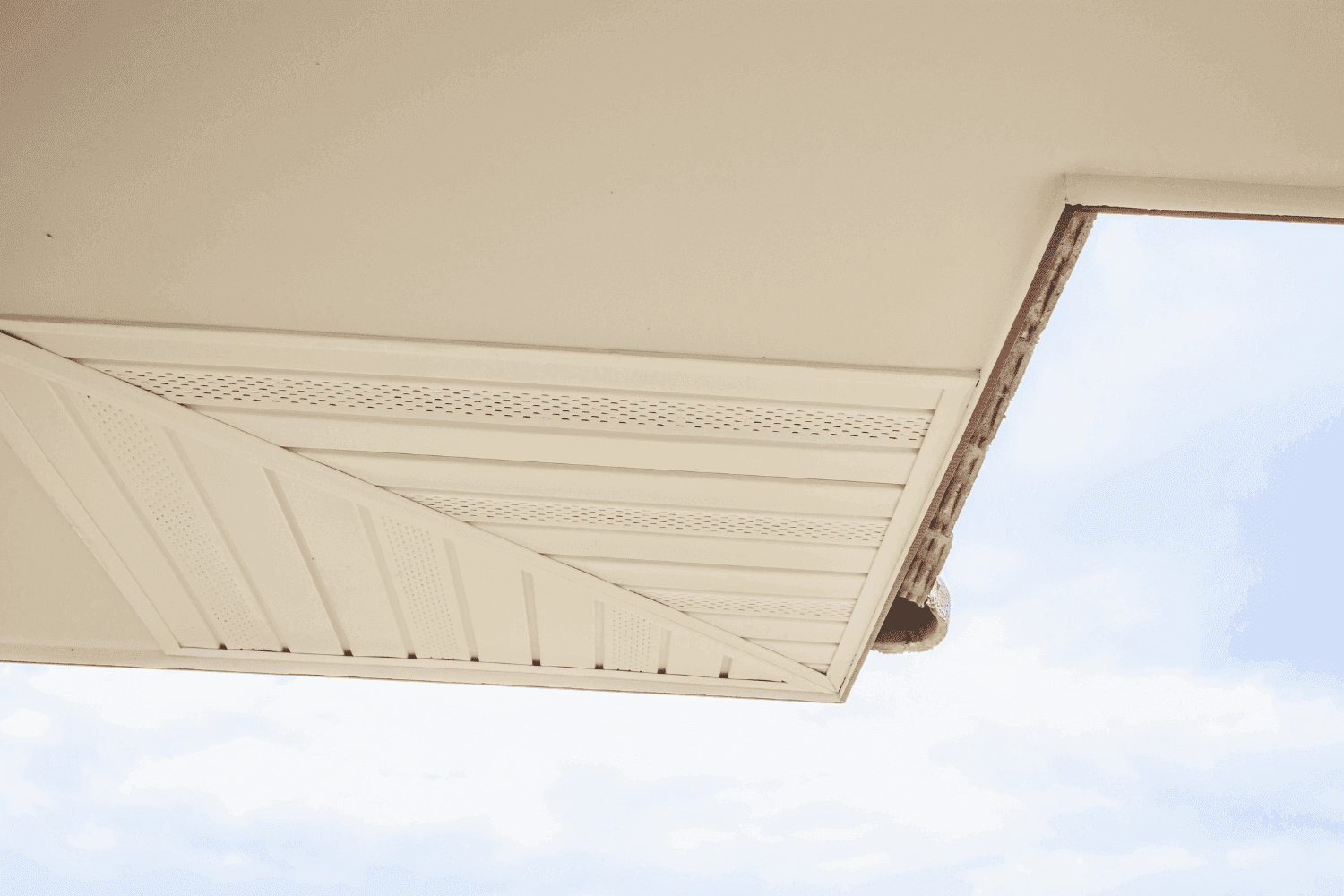

Fascia boards are horizontal boards that run along the edge of the roof, providing structural support and contributing to the overall aesthetic of the home. They are a crucial part of the roofing system, playing multiple roles that go beyond mere decoration, including how fascia supports the overall structure.

These boards support the lower edge of roof shingles and secure the gutter system, ensuring that your home remains protected from weather elements and drip edges.

Definition of Fascia Boards

What exactly are fascia boards? These horizontal boards are located at the edge of the roof and are essential in home construction. They connect to the trusses or rafters, providing a secure base for the gutters and sealing off the attic from the elements. This connection helps maintain the structural integrity of the roof, preventing potential damage from water and debris.

In simpler terms, fascia boards act as a barrier between the edge of the roof and external elements. They support the lower edge of roof shingles, preventing them from curling or cracking over time. Without fascia boards, your home would be more susceptible to weather-related damages, making them an indispensable part of any roofing system.

Importance of Fascia Boards

Fascia boards do more than just hold the gutters in place; they seal off the attic from the harsh elements outside. This not only helps in maintaining the structural integrity of your roof but also keeps your attic free from pests and debris. Imagine the chaos without fascia—snow, rain, and even small animals could easily find their way into your attic, causing significant damage.

From a functional standpoint, fascia boards are essential for protecting the roof structure and supporting the gutter system. They prevent weather elements from damaging the roof and help in maintaining the overall structural integrity of your home. Without them, your roof trusses would be exposed, leading to potential rot and decay over time.

But it’s not all about functionality. Fascia boards also play a significant role in the visual appeal of your home. They cover exposed roof trusses, giving the roof a finished and polished look. This enhances the aesthetic value of your home, making it more appealing to potential buyers and increasing its market value.

Common Materials for Fascia Boards

Homeowners have several options when it comes to choosing fascia boards:

- Wood

- PVC

- Composite

- Aluminum

Each material has its pros and cons, and the best choice often depends on your specific needs and local climate conditions.

Understanding these materials will help you make an informed decision that balances aesthetics, durability, and cost.

Wood Fascia Boards

Wood fascia boards provide a traditional and classic look, enhancing the natural aesthetic of a home. Common types of wood used for fascia boards include cedar, redwood, and fir, each known for its natural beauty and durability. However, wood fascia boards require regular upkeep to prevent issues such as wood rot and moisture damage.

While wood offers a timeless appeal, it is prone to rot and requires constant repainting for protection. This makes it a higher-maintenance option compared to other materials. But for those who value a natural look and are willing to invest in regular maintenance, wood fascia boards can be a beautiful addition to any home.

PVC Fascia Boards

PVC fascia boards are a practical choice for homeowners looking for low-maintenance options. These boards are inherently resistant to moisture and insects, making them highly durable. One of the significant advantages of PVC fascia boards is that they can be painted to match the house trim, allowing for customization and a cohesive look.

PVC fascia boards are also resistant to rot, which means less hassle and maintenance over the years. They offer a modern alternative to traditional wood, providing both durability and aesthetic flexibility. Whether you want a sleek, contemporary look or something that blends seamlessly with your existing decor, PVC fascia boards are worth considering.

Composite Fascia Boards

Composite fascia boards are made from recycled materials, offering both durability and eco-friendliness. These boards are known for their strong resistance to weathering, making them an excellent choice for homes in harsh climates. The use of recycled materials also makes composite fascia boards an environmentally friendly option for homeowners.

Besides their durability, composite fascia boards require less maintenance compared to wood. They are resistant to water and moisture, which means they won’t rot or warp over time.

For homeowners looking for a sustainable and long-lasting solution, composite fascia boards are an ideal choice.

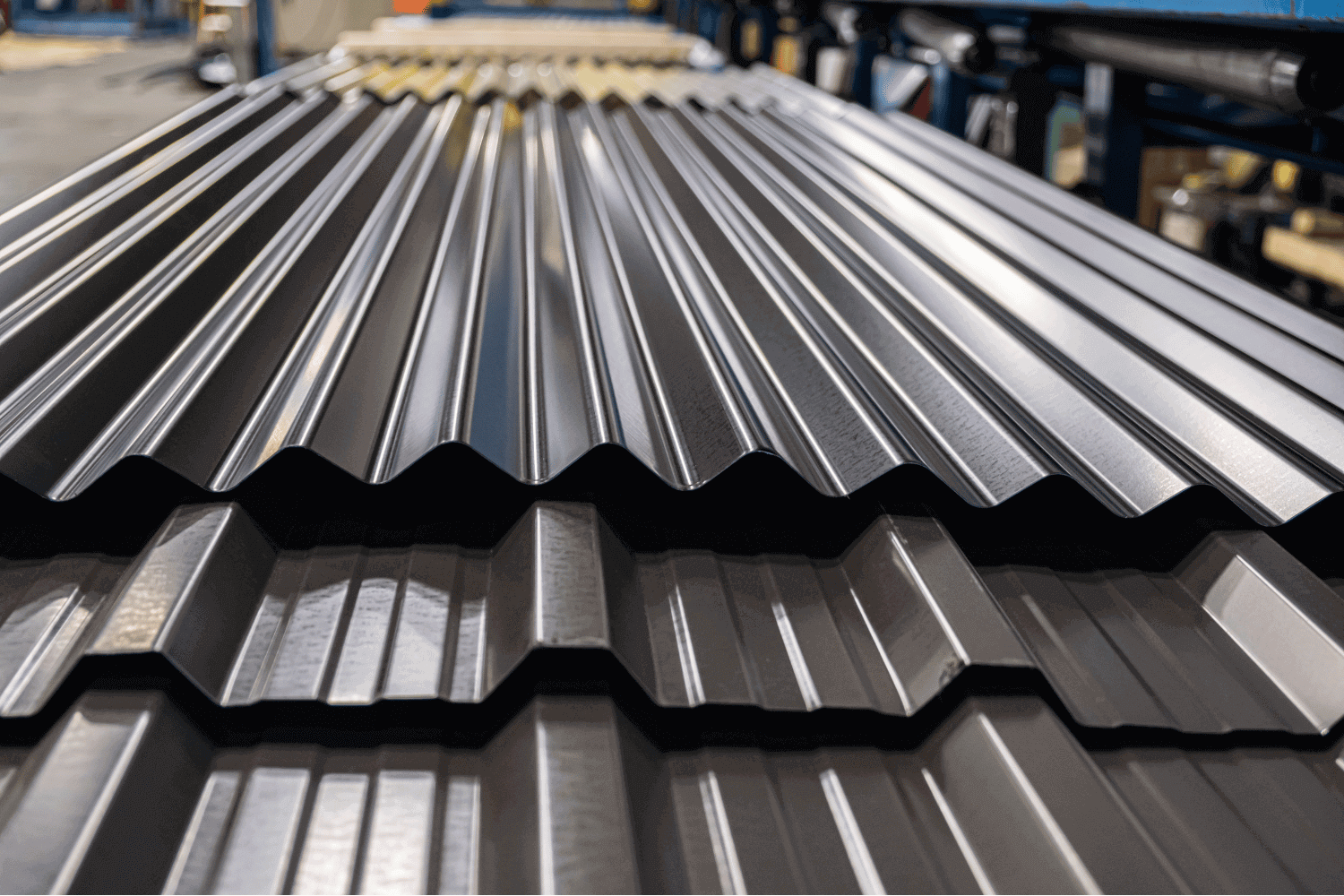

Aluminum Fascia Boards

Aluminum fascia boards are known for their lightweight nature and rust resistance. These characteristics make them easy to handle during installation and require minimal maintenance compared to other materials. However, installing aluminum fascia boards may require specialized techniques to ensure proper fit and durability.

One of the significant benefits of aluminum fascia boards is their rust resistance, which means they can withstand harsh weather conditions without deteriorating. This makes them a durable and low-maintenance option for homeowners looking for long-term solutions.

Choosing the Best Material for Your Home

When selecting materials for your fascia boards, several factors must be taken into account. These include climate, budget, and your aesthetic preferences. Understanding the benefits and drawbacks of different materials will help you make an informed decision that suits your specific needs and enhances the overall look of your home.

Climate Considerations

When selecting fascia boards, it’s crucial to consider weather resistance and local climate conditions. For instance, homes in regions with heavy rainfall should opt for materials resistant to moisture, such as PVC or composite boards. On the other hand, areas with high wind and snow loads might benefit from the durability of aluminum fascia boards.

Climate plays a significant role in the longevity and performance of fascia boards. Choosing the right material can protect your home from bad weather and ensure that your fascia boards remain in good condition for years to come. By considering your local climate, you can select a material that not only looks great but also stands the test of time.

Budget Constraints

Budget is another critical factor when choosing fascia boards. Homeowners should factor in both initial costs and long-term maintenance expenses. While wood fascia boards might be cheaper upfront, they require regular upkeep, which can add to the overall cost over time. On the other hand, composite and PVC boards might be more expensive initially but offer lower maintenance costs.

Balancing cost with performance and longevity is key to ensuring that the selected fascia boards meet both budgetary and maintenance needs. By considering both initial and long-term costs, homeowners can make a financially sound choice that doesn’t compromise on durability or aesthetics.

Aesthetic Preferences

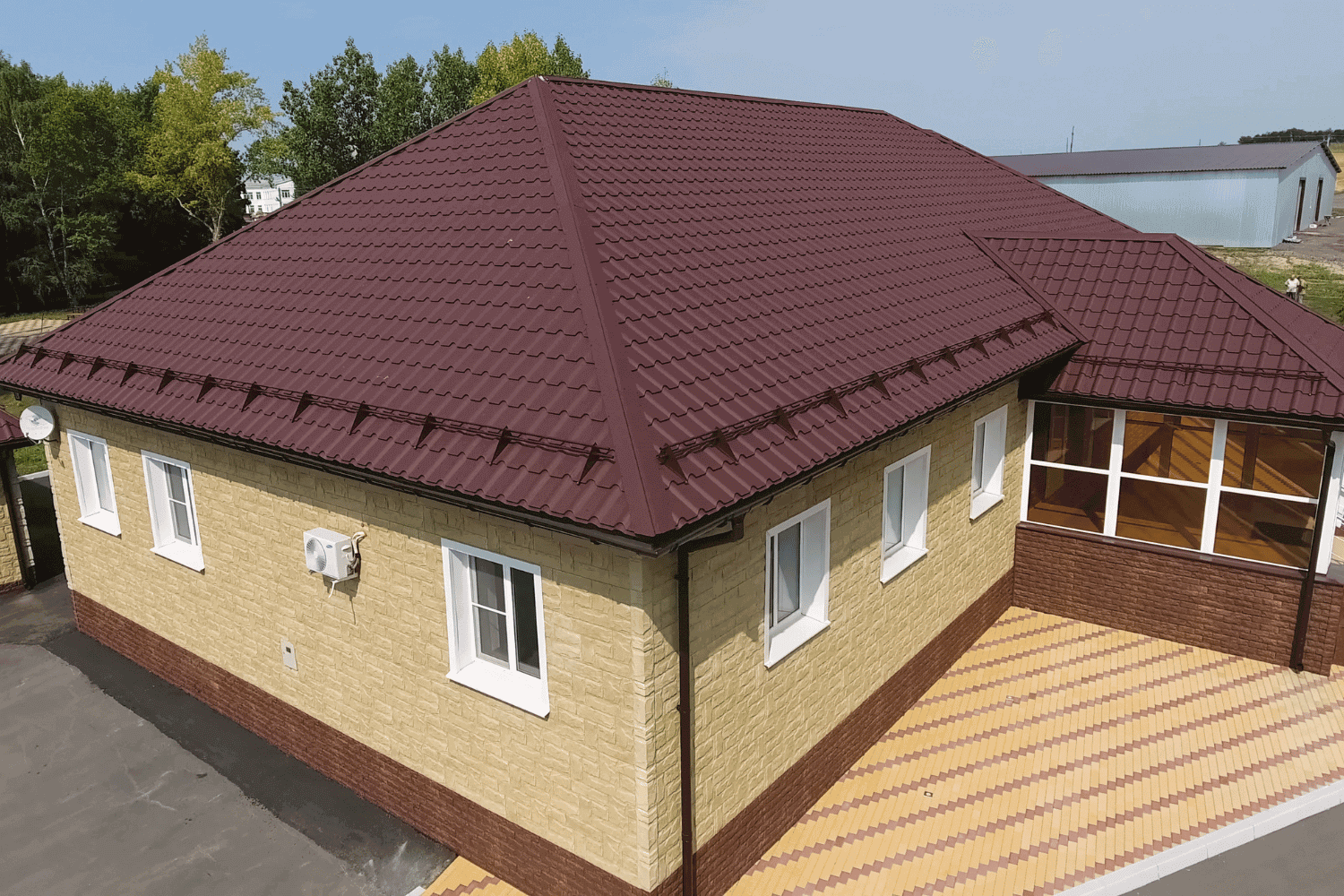

The choice of fascia boards can significantly impact the look of your home. When choosing a fascia color, consider the overall color of the home as well as the color of the roof and trim. Selecting fascia trim colors that harmonize with the existing palette can improve visual coherence and enhance curb appeal.

Whether you prefer a bold contrast or a subtle blend, the right fascia can make all the difference.

Installation and Replacement of Fascia Boards

Installing or replacing fascia boards may seem daunting, but understanding the process can make it manageable. Whether you hire a professional or decide to tackle it yourself, proper installation is crucial for the long-term performance of your fascia boards.

Professional Installation

Hiring a professional roofer for fascia installation ensures proper techniques and long-term performance. Professionals use galvanized or anti-corrosion nails to securely attach fascia boards, preventing future issues. Additionally, installing a metal drip edge helps to prevent water damage to the fascia boards.

After cutting new wood for fascia board installation, it’s essential to seal the wood and apply paint to protect it from moisture. This ensures that the fascia boards are installed properly and remain in good condition for years to come.

Trusting a professional can save you time and ensure that the job is done right.

DIY Installation Tips

For those who prefer a hands-on approach, DIY installation is possible with the right tools and knowledge. Accurate measurement and cutting of the new fascia board are essential to ensure it fits properly and spans at least two rafters for stability. This provides the necessary support and prevents the fascia board from sagging over time.

Sealing the seams against water is another critical step in DIY installation. Using silicone caulk to seal the seams helps prevent water damage and extends the life of the fascia boards.

With careful planning and execution, DIY installation can be a rewarding project that enhances your home’s exterior.

Signs It’s Time to Replace Fascia Boards

Knowing when to replace fascia boards can prevent more significant issues down the line.

Common indicators that it’s time to replace fascia boards include:

- Cracked or curling roof shingles

- Peeling paint

- Leakages

- Discoloration

If your fascia boards are too damaged or weak, they should be replaced as soon as possible to avoid further issues.

Replacing damaged fascia boards not only restores functionality but also enhances the appearance of your home. If your fascia boards detract from the home’s look or are showing signs of significant wear and tear, it’s time for a replacement. Keeping an eye out for these signs can help you maintain the integrity of your roof and overall home structure.

Maintaining Your Fascia Boards

Maintaining fascia boards is essential for preventing moisture infiltration and protecting your home from water-related damage. Regular maintenance can extend the life of your fascia boards and keep them looking good for years to come.

Regular Inspections

Inspecting fascia boards at least once or twice a year is crucial for identifying decay indicators like discoloration or soft spots. Homeowners should look for signs of sagging or drooping, which indicate water damage. Visual checks for cracks, holes, or gaps in fascia boards are also essential in maintaining their structural integrity.

Regular inspections help in early detection of potential issues, allowing for timely repairs and preventing extensive damage. By keeping an eye on your fascia boards, you can ensure they remain in good condition and continue to protect your home.

Cleaning and Painting

Cleaning and painting fascia boards are essential maintenance tasks. Wrapping fascia boards in metal is a recommended method to protect them from moisture damage. Sealed and painted fascia boards should be maintained occasionally to ensure they remain in good condition.

One effective method for cleaning fascia boards involves using gentle soap and water to remove dirt and debris. This not only keeps the boards looking fresh but also helps in identifying any areas that might need touch-ups or repairs.

Regular cleaning and painting can significantly extend the lifespan of your fascia boards.

Gutter Maintenance

Maintaining clean gutters is crucial as they support the fascia boards and protect the roof structure from weather damage. Signs that gutters need replacement include sagging gutters, which can place excess stress on the fascia boards, potentially leading to further damage. Homeowners should perform regular inspections of gutters for debris accumulation and clean them periodically to prevent water damage.

Cleaning gutters can include using a garden hose to flush out debris and checking for proper attachment to ensure they remain securely fastened. Regular gutter maintenance helps prevent clogs that can cause water overflow, leading to fascia board damage, affecting all the guttering.

By keeping your gutters in good condition, you ensure the longevity and effectiveness of your fascia boards.

Enhancing Curb Appeal with Fascia Trim

Fascia boards provide more than just functional benefits; they also enhance the visual appeal of your home by concealing roofing materials and creating a polished edge. Matching fascia materials to other exterior elements can enhance cohesive design, impacting Home value and curb appeal.

The right house fascia trim can dramatically improve the overall look of your home’s exterior and make it more attractive to potential buyers.

Decorative Fascia Trim Options

Decorative fascia trim can feature various designs that align with different architectural styles, from intricate patterns to minimalist designs. Layered decorative fascia trim can add dimension and strength to the home’s exterior. For those who prefer a more subtle approach, fascia trim can ensure a smooth transition to the soffit without drawing excessive attention.

Whether you opt for ornate designs or simple, clean lines, decorative fascia trim can enhance the beauty of your home. The right trim can complement your home’s architecture and reflect your personal style, providing a unique touch that sets your home apart from others in the neighborhood.

Color Coordination

Choosing the right color for fascia boards contributes significantly to the overall curb appeal and visual harmony of your home. Matching fascia colors with the trim, gutters, and siding creates a cohesive and well-designed exterior look. Effective color coordination can enhance curb appeal, making your home stand out positively in the neighborhood.

Exploring different decorative fascia trim colors can add character and individuality to your home’s exterior. Whether you choose to match or contrast colors, the right combination can make a substantial difference in enhancing the aesthetic appeal of your home.

Summary

Fascia boards are an essential component of any home, providing both structural support and aesthetic appeal. From wood to PVC and composite materials, choosing the right fascia boards involves considering various factors such as climate, budget, and personal preferences. Proper installation and regular maintenance are key to ensuring that your fascia boards remain in good condition and continue to protect your home from weather-related damage.

By understanding the importance of fascia boards and how to maintain them, homeowners can enhance the longevity and appearance of their homes. Whether through professional installation or DIY efforts, keeping fascia boards in top shape is an investment in the durability and beauty of your home. Remember, a well-maintained fascia not only protects but also enhances the overall curb appeal of your Home.

Frequently Asked Questions

What is the difference between a trim board and a fascia board?

A trim board frames windows and doors, giving your home a finished look, while a fascia board covers the edges of the eaves, providing protection and support for the roof. Each serves a unique purpose in enhancing your home’s exterior.

What are fascia boards, and why are they important?

Fascia boards are crucial as they sit at the edge of your roof, supporting shingles and holding up gutters while protecting your roof structure from weather damage. Without them, you risk structural issues and water damage.

What are the common materials used for fascia boards?

Fascia boards typically use materials like wood, PVC, composite, and aluminum. Your choice will depend on your budget and how much maintenance you’re willing to handle!

How can I tell if my fascia boards need to be replaced?

If you notice cracked or curling shingles, peeling paint, leaks, or discoloration, it’s a clear sign your fascia boards may need replacement. Don’t wait too long—addressing these issues can save you from bigger problems down the line.

How often should I inspect my fascia boards?

You should inspect your fascia boards at least once or twice a year to catch any signs of decay like discoloration or sagging. Regular checks will keep them in good shape and looking great!

574-318-3326

574-318-3326