Top Corrugated Metal Roof Options for Durable, Stylish Protection

Curious about the benefits of corrugated metal roofs? This guide breaks down why this roofing type is favored for durability, cost-effectiveness, and ease of maintenance. You’ll learn about different material options, installation costs, and long-term savings, helping you decide if a corrugated metal roof is right for you.

Key Takeaways

-

Corrugated metal roofing offers durability, low maintenance, and customizable design options, making it suitable for various applications, including residential, commercial, and agricultural settings.

-

The cost of corrugated metal roofing ranges from $7.00 to $13.00 per square foot, with long-term savings due to its energy efficiency and extended lifespan of up to 70 years.

-

The installation process, while requiring precise measurements and specialized skills, benefits from the lightweight nature of the materials, facilitating easier handling and quicker project completion.

Top Corrugated Metal Roof Options for Durable, Stylish Protection

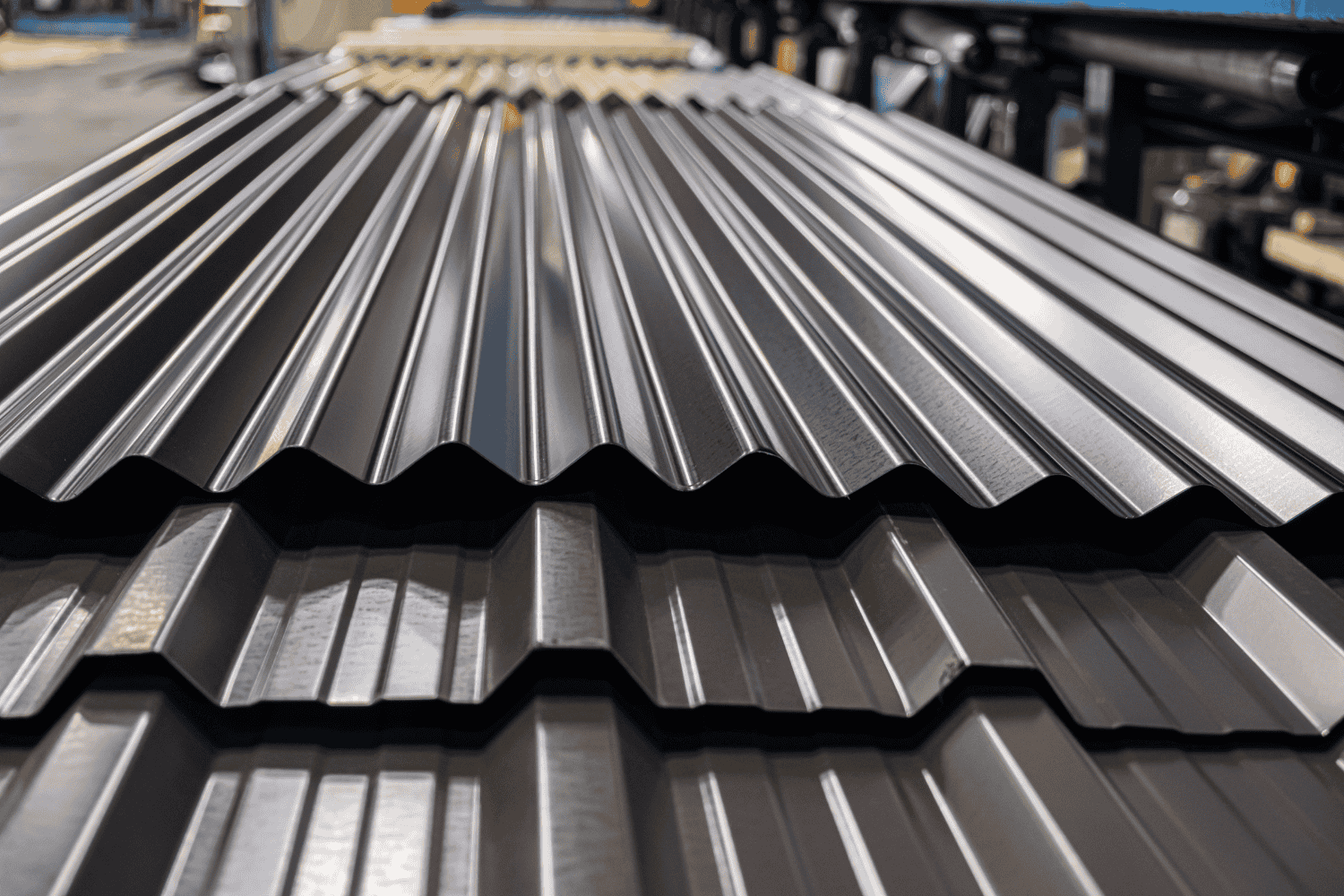

Corrugated metal roofing panels are crafted from sheets of corrugated sheet metal that are roll formed into a series of ridges and grooves, enhancing their strength and stiffness. Typically made from steel or aluminum, these corrugated panels feature a wavy design that promotes water drainage and structural integrity. Customization options abound, including variations in panel size, thickness, and material type, allowing for tailored solutions that meet both aesthetic and functional needs.

The cost of corrugated metal roofing can vary significantly, ranging from $7.00 to $13.00 per square foot for materials and installation. Factors such as material choice, installation complexity, and additional features can influence the overall expense, which can range from $15,000 to $50,000 for a complete roof.

Despite the initial investment, the durability and low cost maintenance requirements of corrugated metal roofs offer long-term savings and peace of mind for Home owners.

Introduction

Corrugated metal roofing has become a go-to option for many due to its unique characteristics and advantages. Its versatility and aesthetic appeal have significantly contributed to its growing popularity. Whether it’s for residential homes or commercial buildings, corrugated metal roofing offers a blend of attractiveness and affordability, making it a reliable choice for a wide range of construction needs.

The Metal Roofing Learning Center offers detailed information for those looking to explore the various options available for corrugated metal roofing. Here, you can find detailed information to guide you through the selection process, ensuring you choose the perfect fit for your project. From panel sizes and shapes to material types and finishes, the options are vast and varied, catering to all sorts of architectural styles and requirements.

Corrugated Metal Roofing Panels Overview

Corrugated metal roofing panels are designed to enhance both the strength and stiffness of the roof. These panels, typically made from steel or aluminum, feature a wavy or corrugated design that not only adds to their structural integrity but also promotes efficient water drainage. Customization options are plentiful, allowing for variations in panel size, thickness, and material type to meet specific needs.

The aesthetic and functional benefits of metal roofing are further enhanced by the availability of various shapes and sizes. Additional trims and accessories can also be integrated to boost both the performance and visual appeal of the roofing system. Whether you’re looking for a modern, industrial look or a more traditional style, corrugated metal roofing offers the flexibility to achieve your desired outcome.

Material Options

Corrugated metal roofing panels are primarily constructed from materials like steel, aluminum, copper, and zinc, each offering unique advantages. Galvanized steel, for example, is coated in zinc to provide rust resistance, making it particularly effective in coastal areas with high humidity. Corrugated steel is favored for its high tensile strength and ability to shed water effectively, which is ideal for regions with heavy rainfall.

Another popular material is Galvalume steel, which features a coating of zinc, aluminum, and silicone, offering enhanced durability and self-healing properties. Aluminum, known for its lightweight nature, is also highly resistant to corrosion, making it suitable for various climates, especially coastal areas.

The choice of material significantly impacts both the cost and performance of the roofing system, with higher gauge steel providing better durability and lower maintenance costs over time.

Key Features

One of the standout features of corrugated metal roofing is its ability to withstand extreme weather conditions, including high winds and heavy rainfall. These panels are lightweight, which simplifies installation and reduces structural load, ultimately lowering building costs. The lightweight nature of these panels also facilitates easier handling during installation, allowing for quicker project completion.

The corrosion resistance of materials like Galvalume and galvanized steel ensures longevity by preventing rust. Additionally, the choice of paint finish can affect the roof’s longevity and maintenance needs, with some finishes requiring less upkeep than others.

Overall, the combination of durability, ease of installation, and low maintenance makes corrugated metal roofing a highly attractive option for many Home owners.

Benefits of Choosing Corrugated Metal Roofing

Corrugated metal roofing is recognized for its combination of durability, energy efficiency, and modern aesthetics. These roofing panels are praised for their strength, cost-effectiveness, and ability to withstand severe weather conditions like hail, storms, and heavy rains without leaking. The affordability and aesthetic appeal of corrugated metal roofs make them an increasingly popular choice among homeowners.

In addition to their practical benefits, corrugated metal roofing is also an environmentally friendly option. These roofs are recyclable, addressing environmental concerns in construction and contributing to a more sustainable building practice.

The significant advantages of corrugated metal roofing—durability, energy efficiency, and low maintenance—make it a compelling option for a wide range of applications.

Longevity and Durability

Corrugated metal roofs can last over 50 years with proper installation and maintenance, far exceeding the typical lifespan of asphalt shingles. These roofs can endure extreme weather conditions, including high winds and heavy rain, with a lifespan ranging from 40 to 70 years. The durability of these roofs minimizes the frequency of replacements, contributing to long-term cost efficiency.

The longevity of corrugated metal roofs also leads to reduced repair costs and lower energy bills over time. For commercial and agricultural applications, the low maintenance needs of these roofs are particularly advantageous. Overall, the combination of durability and minimal upkeep makes corrugated metal roofing a smart investment for any Home.

Energy Efficiency

Corrugated metal roofs can significantly improve indoor comfort by reflecting heat, thus saving on cooling costs. Homeowners can see energy savings of around 40% with metal roofs, as they reflect heat, particularly benefiting those in warmer climates with pre-painted options. Insulated corrugated metal roofs can reduce energy bills by up to 40% due to their ability to retain warmth in the winter and reflect heat in the summer.

Many corrugated metal roofs feature reflective coatings that help keep homes cooler in summer and warmer in winter. These reflective coatings can further maximize energy savings by minimizing heat absorption.

Overall, the energy-efficient properties of corrugated metal roofs can result in significant utility savings, enhancing their appeal for both residential and commercial properties.

Low Maintenance Requirements

Corrugated metal roofs are designed to require minimal maintenance, saving time and money for homeowners. These roofs typically need only periodic re-coating and fastener checks, along with occasional cleaning to remove debris. Regular checks for loose fasteners and signs of corrosion are recommended to ensure the integrity and longevity of the metal roof.

Compared to traditional roofing materials, corrugated metal roofs can last for many years without major maintenance. This low maintenance requirement makes corrugated metal roofing an attractive option for Home owners seeking a durable and hassle-free roofing solution. The combination of ease of upkeep and long-lasting performance underscores the value of choosing corrugated metal roofing.

Installation Process for Corrugated Metal Roofing

The installation of corrugated metal roofing involves several key stages, including preparation, actual installation, and post-installation inspection. These roofs are lightweight and easy to install, which can lower overall building costs. The installation process requires precise measurements and the use of overlapping panels for effective coverage.

Post-installation inspection is crucial to ensure that the corrugated metal roofing is secure and properly aligned. By following the proper steps, homeowners can ensure a durable and long-lasting roof that offers excellent protection against the elements.

The installation process consists of several key stages, each crucial for ensuring a durable and effective roof.

Preparation and Planning

The installation of corrugated metal roofing requires careful planning and adherence to specific steps to ensure durability and effectiveness. Accurate measurements of the roof area are essential for determining the amount of corrugated metal needed for installation. When planning, ensure the roof framing allows for purlins spaced no more than 36 inches apart for optimal panel support.

Employing proper fastening techniques is key to securing corrugated metal panels and preventing future issues. By taking these preparation steps seriously, homeowners can avoid common pitfalls and ensure a successful installation process. Proper planning and preparation set the stage for a smooth and efficient installation.

Installation Steps

The installation process for corrugated metal roofing is more complex and requires specialized skills, resulting in higher labor costs compared to asphalt shingle installation. The complexity of the roof design can increase labor costs, especially if specialized installation techniques are needed. However, the lightweight nature of corrugated metal allows for easier installation and less material for structural support.

The installation time varies based on the size and complexity of the roof, but the overall process is generally quicker than other roofing types due to the lightweight composition of the panels. Following a step-by-step guide ensures that each panel is installed correctly and securely, providing a durable and reliable roofing solution. Proper installation techniques are essential for maximizing the lifespan and performance of the roof.

Post-Installation Inspection

Conducting a detailed inspection after installation ensures that all panels are securely fastened and properly aligned. After installation, check for proper alignment of panels and seal any visible seams to prevent leaks. Inspect the roofing for proper fastening; screws should be snug but not over-tightened to avoid panel distortion.

A thorough inspection after installation helps to identify any misalignments or loose fasteners that could lead to problems down the road. By addressing any issues immediately, homeowners can ensure the long-term durability and performance of their corrugated metal roofing system. Post-installation inspection is a critical step in the installation process, providing peace of mind and confidence in the quality of the roof.

Customization Options for Corrugated Metal Roofing

Customization options for corrugated metal roofing allow homeowners to personalize the look of their roofs. Common design styles for corrugated metal panels include farmhouse and industrial themes. These roofing panels can be tailored with various profiles and textures to meet specific design preferences.

The ability to customize corrugated metal roofing extends beyond aesthetics to include functional enhancements. Trims and accessories can be added to improve both the performance and visual appeal of the roof. Exploring the various customization options, such as color choices, profiles, textures, and trim, allows homeowners to personalize their roofs to match their preferences.

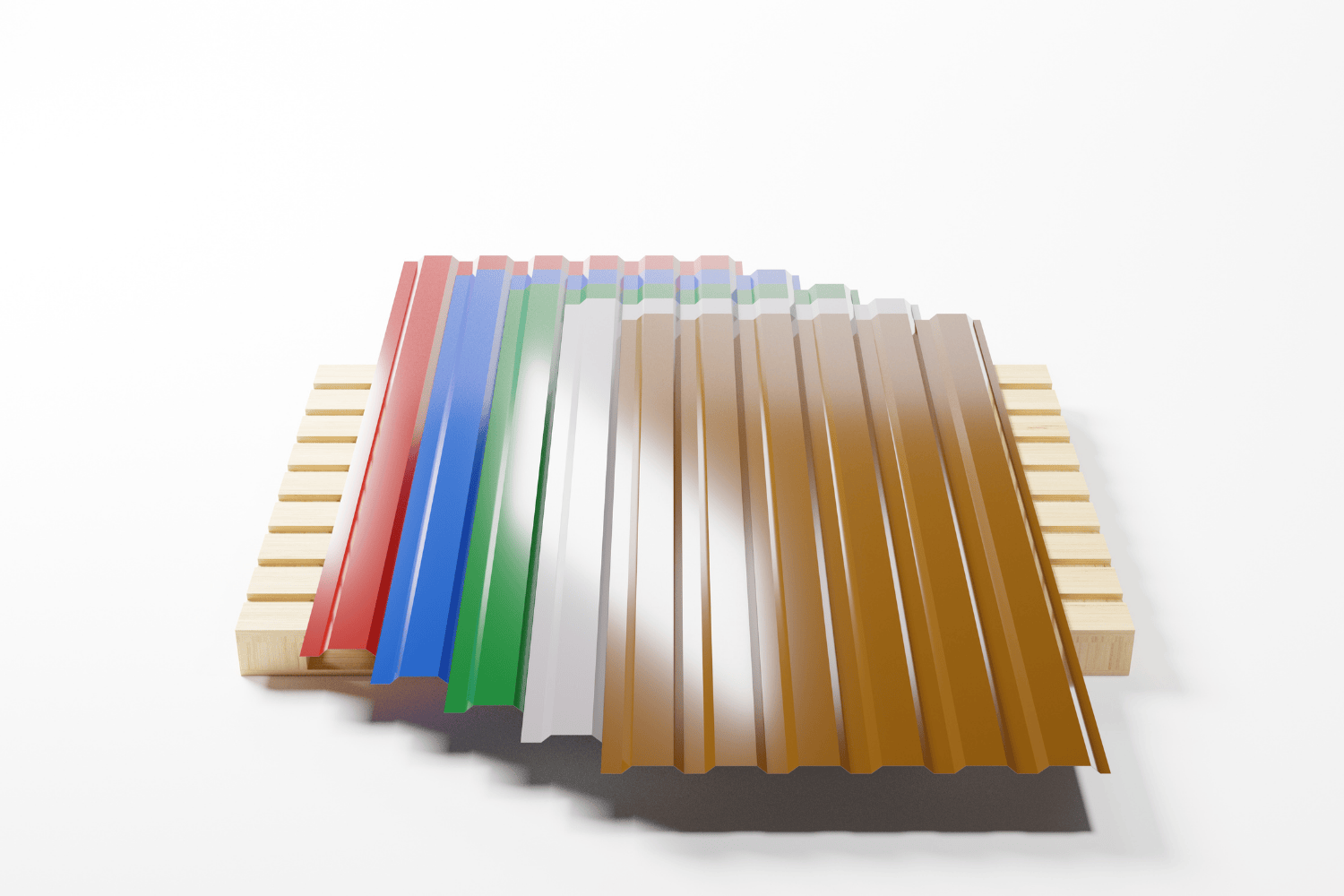

Color Choices

Corrugated metal roofing offers a wide range of color options to suit various design preferences and styles. One of the available options in corrugated metal roofing colors is the streaked series, which provides a unique visual effect. To ensure that the chosen color for corrugated metal roofing matches expectations, it is recommended to verify colors using actual metal samples.

With a variety of colors to choose from, homeowners can select the perfect shade to complement their Home’s exterior. Whether you prefer classic silver or a bold, vibrant hue, the color options available for corrugated metal roofing can help achieve the desired look. The ability to customize the color of your roof adds a personal touch and enhances your Home’s curb appeal.

Profiles and Textures

Different textures can be applied to metal roofing materials to enhance their visual appeal and character. Textures in corrugated metal can range from smooth finishes to embossed patterns. These profiles and textures provide unique styling options for homeowners and businesses, allowing them to achieve a distinctive look that complements their overall design aesthetic.

The choice of profile and texture can significantly impact the roof’s appearance and functionality. For instance, a smooth finish might be ideal for a modern, sleek look, while an embossed pattern can add a touch of elegance and sophistication. By experimenting with different profiles and textures, Home owners can create a customized roofing solution that truly stands out.

Trim and Accessories

Trim options for corrugated metal roofs include eave trim, valley trim, and ridge caps. These trims and accessories provide enhanced functionality and aesthetic appeal to the roofing system. Eave trim helps direct rainwater away from the roof edges, preventing water damage, while valley trim maintains the integrity of the roof’s structure by channeling water runoff.

Ridge caps are used at the peak of the roof to provide a finished look and protect against moisture intrusion. Using the right trims and accessories not only enhances the visual appeal but also boosts the longevity of corrugated metal roofing. Properly selected and installed trims and accessories can make a significant difference in both the performance and aesthetics of your roofing system.

Cost Considerations for Corrugated Metal Roofing

Corrugated metal roofing is considered more affordable than many other metal roofing styles, making it an attractive option for budget-conscious buyers. Before installation, it’s essential to measure the roof area and calculate the total square footage required, adding approximately 15% for overlaps. The overall cost of a corrugated metal roof is influenced by factors such as material choice, installation complexity, and additional features required for installation.

Corrugated metal roofs typically require minimal maintenance, needing only occasional inspections and a recoat for longevity. This low maintenance requirement contributes to significant long-term savings compared to other roofing materials. By investing in corrugated metal roofing, homeowners can enjoy a durable and cost-effective solution that requires less upkeep over time.

Factors Influencing Cost

The choice of material significantly impacts the cost of corrugated metal roofing, as prices can range from $3.50 to $6.50 per square foot for basic options. Smaller roofing projects often incur higher costs per square foot, with potential increases of 20% to 100% for jobs under 1,000 square feet. The overall cost is also influenced by the complexity of the installation process, as more intricate designs may require additional materials and labor.

Purchasing directly from manufacturers can lead to significant savings, ranging from 15% to 50% compared to buying through distributors. By carefully considering these factors, homeowners can make informed decisions that align with their budget and project requirements. Understanding the cost drivers helps in planning and optimizing the investment in corrugated metal roofing.

Long-Term Savings

The low maintenance requirements of corrugated metal roofs contribute to significant long-term savings compared to other roofing materials. While metal roofing often has a higher upfront cost, its longevity, energy efficiency, and low maintenance requirements make it cost-effective in the long run. The durability of corrugated metal roofs means they can withstand harsh weather conditions over time, contributing to substantial long-term savings.

Overall, by investing in corrugated metal roofing, homeowners can expect substantial savings over time due to its durability and minimized upkeep. The initial investment is offset by the reduced need for repairs and replacements, making corrugated metal roofing a wise financial choice for the long term.

Comparing Corrugated Metal Roofing to Other Roofing Types

Corrugated metal roofs are a versatile option that can provide durability and efficiency compared to traditional roofing materials. Common materials used for corrugated metal roofing include galvanized steel, Galvalume, and aluminum. Corrugated metal roofing offers a longer lifespan and requires less maintenance than asphalt shingles, which can lead to significant cost savings over time.

While standing seam metal roofs offer similar longevity to corrugated metal roofs, they tend to be more expensive due to their construction and installation requirements. Understanding the differences between these roofing types helps homeowners make informed decisions based on their budget, aesthetic preferences, and maintenance capabilities.

Let’s delve into specific comparisons to highlight the benefits and drawbacks of each option.

Corrugated Metal vs. Asphalt Shingles

Corrugated metal roofs are known for their exceptional durability, lasting up to 50 years or more, while an asphalt shingle roof typically has a lifespan of 20-30 years. Metal roofs are highly resistant to extreme weather conditions, including strong winds and heavy snow, whereas asphalt shingles may suffer from damage under similar conditions.

Although upfront installation costs for corrugated metal roofing are typically higher compared to asphalt shingles, the long-term savings can make metal roofs a more cost-effective choice. Asphalt shingles, while cheaper to install initially, have a shorter lifespan and may require more frequent replacements, leading to higher overall costs.

Additionally, corrugated metal roofs require minimal maintenance, usually just periodic cleaning, while asphalt shingles need regular inspections and may require repairs after weather events. This comparison highlights the long-term benefits of choosing corrugated metal roofing over asphalt shingles.

Corrugated Metal vs. Standing Seam Metal Roofs

The two types of metal roofing panels compared are exposed fastener panels and standing seam panels. Standing seam metal roofs typically feature concealed fasteners, which provide a sleeker appearance and potentially better weather resistance compared to corrugated metal roofs. Concealed fasteners found in standing seam roofs reduce the risk of leaks compared to the exposed fasteners of corrugated metal roofing.

The lifespan of a standing seam metal roof can exceed 75 years, significantly outlasting corrugated metal options. However, the higher cost of standing seam metal roofs may be a consideration for budget-conscious homeowners.

By comparing the aesthetics, installation requirements, and costs of these two metal roofing types, Home owners can make an informed decision that best suits their needs.

Common Applications of Corrugated Metal Roofing

Corrugated metal roofing is used in diverse settings, including residential construction, agricultural barns, and commercial buildings, due to its strength and weather resistance. This type of roofing enhances commercial building value through reliable weather protection and longevity. In agricultural settings, corrugated metal roofing is favored for its resistance to harsh weather conditions.

The versatility of corrugated metal roofing makes it suitable for a variety of applications, from sheds and outbuildings to barns and residential homes. Its resilience and adaptability make it a practical and reliable choice for Home owners in different sectors.

Examining the specific applications in residential, commercial, and agricultural contexts highlights the versatility of corrugated metal roofing.

Residential Use

In residential settings, corrugated metal roofs provide a mix of aesthetic appeal and protection, making them suitable for homes, sheds, and garages. This type of roofing can offer a modern aesthetic while enhancing a home’s durability against the elements. Homeowners appreciate the combination of style and functionality that corrugated metal roofing brings to their properties.

By choosing corrugated metal roofing, homeowners can enjoy a roof that not only looks great but also provides robust protection against harsh weather conditions. The modern and sleek appearance of corrugated metal roofing can complement various architectural styles, adding to the overall curb appeal of residential properties.

Commercial and Agricultural Use

Agricultural structures like livestock shelters and crop storage benefit from the weathertight seal that metal roofing provides. Corrugated metal roofing is a popular choice for commercial buildings and agricultural structures due to its durability and low maintenance requirements. In commercial buildings, the longevity of corrugated metal roofing reduces the frequency and cost of replacements, making it a smart investment.

Overall, the versatility, cost-effectiveness, and reliability of corrugated metal roofing make it an excellent choice for both commercial and agricultural use. Home owners in these sectors can rely on corrugated metal roofing to provide long-lasting protection and minimal upkeep, ensuring their buildings remain in top condition for many years.

Summary

Corrugated metal roofing stands out as a durable, energy-efficient, and low-maintenance option suitable for a variety of applications. From residential homes to commercial and agricultural buildings, this roofing type offers significant benefits that make it a compelling choice for many Home owners. The ability to customize the look and function of corrugated metal roofing further enhances its appeal, allowing for tailored solutions that meet specific needs and preferences.

Investing in corrugated metal roofing can lead to long-term savings and peace of mind, thanks to its longevity and minimal maintenance requirements. As you consider your roofing options, remember that corrugated metal roofing combines practicality with aesthetics, offering a reliable and stylish solution for protecting your Home. Embrace the advantages of corrugated metal roofing and make a choice that will serve you well for decades to come.

Frequently Asked Questions

What services does A&M Home Services offer for metal roofing in Indiana?

A&M Home Services provides installation, repair, and maintenance for metal roofing on residential and commercial properties in Indiana. This ensures durable and long-lasting roofing solutions for their clients.

How does metal roofing perform in extreme weather conditions?

Metal roofing excels in extreme weather conditions due to its durability, effectively resisting heavy rain, high winds, and hail. This resilience makes it a reliable choice for protection against the elements.

Is metal roofing more expensive to install compared to other roofing types?

Metal roofing typically has a higher initial installation cost than other roofing types, but its durability and energy efficiency can make it more economical over time.

What maintenance is required for a metal roof?

To ensure your metal roof remains in optimal condition, conduct regular inspections for loose fasteners, proper panel alignment, and any signs of corrosion. Addressing these issues promptly will help maintain the longevity of your roof.

What factors influence the cost of installing a metal roof?

The cost of installing a metal roof is primarily influenced by the roof size, material selection, and complexity of the installation. These factors collectively determine the overall expense.

574-318-3326

574-318-3326